Whether you’re a coffee lover, or just getting into it, this one’s for you.

Beanworks have been roasting coffee for over 20 years – tweaking, tasting, and chasing bold flavour every step of the way. The coffee roasting process is how a green seed turns into something rich, complex and read to brew.

Let’s break it down, from seed to sip.

The Journey Before the Roast

Green coffee beans are the seeds of the coffee cherry. Roasting is what unlocks their potential – building body, sweetness, acidity, aroma, and rich flavours… everything that makes coffee coffee.

Before we start spinning beans in the drum of our roasters here in Northampton, coffee begins its story in a far humbler state – bright, fresh cherries plucked from the branch. But the magic doesn’t start with fire. It starts with fermentation, drying, washing and most importantly, time. This is called coffee processing and it happens at origin (in the countries where the coffee is grown). It’s the quiet hustle behind every green bean’s glow-up, transforming fruit into something roast-ready.

There are three main coffee processes that the majority of our coffees originate from: natural, semi-washed or washed. Each one rewrites the flavour script long before the beans are roasted.

• Washed (Wet): The fruit is stripped off the bean early. What you get in the cup is usually crisp and more acidic.

• Semi-Washed (Honey): The outer layer of the coffee cherry is removed, but the sticky mucilage is left on. These coffees are often sweet and syrupy with more body.

• Natural (Dry): The whole cherry is left to dry with the seed inside, and then the dry skin and pulp is taken off. Expect bold, fruity, and often funky flavour. Great if you like your coffee with a bit of personality.

However your beans were grown and processed, they arrive at our roastery as green, dry whispers of their former selves. And from here, the real transformation begins in the capable hands of the Beanworks team. Roasting turns chemistry into craft, and potential into pour-over poetry.

What is Coffee Roasting?

So, what actually is coffee roasting – and why do we do it?

The National Coffee Association puts it like this:

“Roasting coffee is a process that uses heat to transform raw, green coffee beans into the fragrant, brown coffee beans we know and love.”

How Are Coffee Beans Roasted?

Most coffee beans are roasted using a drum roaster. Beans spin in a rotating metal drum over a heat source, cooking evenly as the drum turns. The Beanworks roastery is home to a 15 and 30 kg Giesen roaster. These beasts are, in our opinion, the best in the biz and make light work of transforming our carefully sourced and processed green coffee beans into the incredible profiles that our team create.

But this isn’t the only coffee roasting method – another popular option is the fluid bed roaster. Instead of a drum, beans are suspended on a stream of hot air. Think of them floating and swirling as they roast.

Drum roasting and hot air roasting are both used across the coffee industry, and they can both produce incredible coffee. It’s all about how the roaster uses the tool to bring out the best in each bean.

What is the Coffee Roasting Process?

The roasting process of coffee, explained step-by-step. Find out how your favourite brew comes to life.

Caramelisation & the Maillard Reaction

This is where the transformation really takes off! The roaster is heated to 200–230°C and the beans are put in for 10–15 minutes, depending on the roast.

The Maillard Reaction is the star of the show – when sugars and amino acids react under heat, turning the beans brown and generating all of your favourite flavours. The temperature at this stage and how the long the beans are left in for affects everything – from acidity and sweetness to body and finish. Great roasters refine their roasts for each type of bean to make sure the flavour hits just right.

Cracking

As beans build up heat, they eventually reach a point where they release it – known as an exothermic reaction. That’s when the first crack happens, which is literally the coffee beans cracking open, and sounds like popcorn popping.

How long the beans are roasted for past this point will affect the final flavour. For a darker roast, you might wait for a second crack – but push it too far and the flavours can flatten. Timing here is everything.

Cooling

As soon as the roast hits its peak, it’s time to cool the beans. Beans are dropped into a cooling tray to stop the roast in its tracks. If they keep cooking, the flavours can flatten or overdevelop. Fast cooling means the character of the roast stays locked in.

Quality Control

While the beans cool, it’s also time to spot and remove anything that doesn’t belong in a high-quality batch:

• Quakers – Underdeveloped beans with low sugar, which won’t caramelise properly. These are easy to spot as they’re lighter in colour than the other beans.

• Pea berries – A natural variation where one round bean grows instead of two, resulting in a pea-shaped coffee bean. They can be amazing on their own, but they’ll affect the consistency of the roast if left in the batch with the other beans.

• Broken beans – Like pea berries, these are not ideal for consistent roasting and best removed.

Packaging

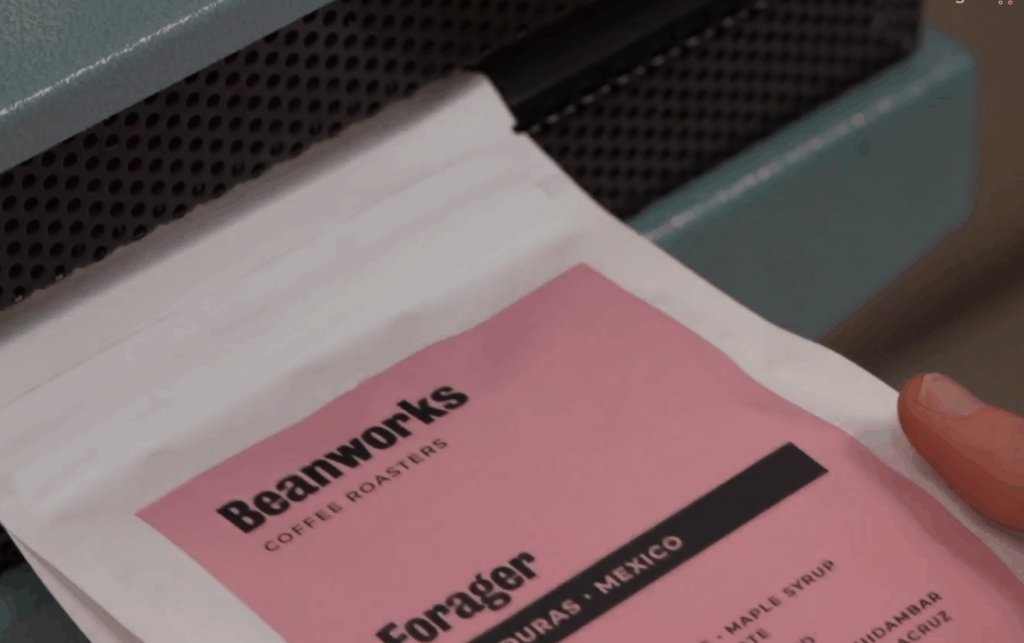

Now the beans are ready to be packaged up, but it’s not quite as simple as it sounds. Freshly roasted beans release carbon dioxide for several days, which is completely natural. But to keep them from going stale, the packaging has to let that gas out – without letting oxygen in.

At Beanworks, we use valve-sealed bags. These let the coffee de-gas safely while staying protected from air, light, and moisture. It means your beans keep doing their thing post-roast – and by the time you open the bag, they’re at their flavour peak.

Colour Changes in the Coffee Bean Roasting Process

Below, you can see how coffee beans start out before they’re roasted and the colour changes they go through as they head toward peak flavour and are ready to start cooling.

It begins with a creamy colour as the beans start to lose moisture and soften during the drying stage. As the heat builds and the Maillard reaction gets underway, the beans turn a chestnut brown – this is when sugars and amino acids begin transforming into flavour. Finally, they shift to a rich, chocolatey-brown as caramelisation takes hold, bringing out those bold, deeper notes that give the coffee body and sweetness.

Light, Medium and Dark Roasts

A coffee’s roast level tells you what kind of ride you’re in for, and how the coffee’s personality shows up in the cup. Remember the Maillard reaction and its friend, the first crack? They’re what determine whether you’ll get a light, medium or dark roast.

• Light Roast: The Maillard reaction is shorter, and the roast usually ends just after first crack. You’ll get higher acidity, delicate sweetness, and fruity or floral notes.

• Medium Roast: Roasted a bit longer to balance acidity, body, and sweetness.

• Dark Roast: We’re going for the second crack. Acidity mellows out, body thickens, and flavours deepen into chocolate, spice, or toasted nuts.

When and Why Does Coffee Roasting Go Wrong?

Even with the best beans, things can go off track. Here’s what can cause a roast to go wrong:

• Pushed too far: Over-roasted beans have a bitter flavour and taste ashy or burnt.

• Low-quality green beans: If the coffee was picked too early or poorly sorted, it might not have enough natural sugars to caramelise – which means flat, hollow flavour. These are the quakers we talked about earlier.

• Inconsistent bean size: Uneven beans roast at different speeds. That’s like trying to toast big and small marshmallows in one batch – some are burnt, others are raw. No thanks.

That’s why we’re picky at every stage, from sourcing to sampling, from profiling to post-roast checks. We roast because we love it, but also because we care about what ends up in your cup.

Beanworks: For Better Coffee Everyday

Whether you’re brewing at home or buying for your café, you get coffee that lives up to the hype.

Roasted with purpose. Packed with personality.

Shop now and serve coffee with character – the kind people remember.